About us

Everything you should know about us

Farabin Process Sharif Company started its production of raw materials for the polyurethane industry in 2022. This knowledge-based company was established with the goal of localizing the raw materials used in industries, especially the automotive industry, in collaboration with a group of faculty members from Sharif University of Technology and experienced industrial managers. In a short period, it managed to announce its presence in the market by producing over 1000 tons of products.

With an operational license for producing 5000 tons per year solely for automotive polyurethane raw materials, and an annual production capacity of over 8000 tons in a single work shift, this company is now considered one of the top producers in the country in this field. Collaborating with major industrial companies, including those in the Iran Khodro and Saipa industrial groups, as well as several private companies, are among the achievements of this company.

Farabin Process Sharif’s use of specialists and innovators, mostly members of the faculty and graduates of Sharif University of Technology, along with its standard research and development infrastructure, technological cooperation with reputable international brands, and very suitable production-equipment infrastructure, combined with adherence to professional after-sales service principles, has enabled this company to produce various polyurethane systems. On the other hand, the company’s organizational culture, which prioritizes competitiveness and customer satisfaction over temporary profit, and considers its competitive advantage in innovation, engineering precision, and close ties between industry and academia, has elevated the brand (FORMAX) as one of the top producers of polyurethane systems in the country.

It is worth mentioning that in 2022, this company obtained a knowledge-based license from the Vice Presidency for Science and Technology. With the support of its human resources and highly suitable production equipment, this company has succeeded in producing and offering various raw materials for different industries such as automotive, footwear, household appliances, and foam and sponge.

Industry-University Connection

Farabin Frayand Sharif, located in the Science and Technology Park of Sharif University of Technology, has established a deep link between industry and academia in its field. This connection not only provides access to the latest scientific achievements and modern technologies but also, by utilizing the knowledge and expertise of university professors and researchers, leads to the practical application of academic research, the development of innovative products, and the improvement of production processes. The company’s ongoing collaborations with Sharif University of Technology have always created added value for both parties, allowing the industry and academia to mutually benefit from each other’s advantages. Based on this, Farabin Farayand Sharif is ready for any scientific, operational, and production collaboration with other companies, organizations, universities, and students in the country. Defining joint scientific and executive projects is among the initial proposals for cooperation with the company.

Research and Development Unit (RD) of Farabin Farayand Sharif is the beating heart of innovation and progress in this company. This unit continuously develops new products and improves existing ones by utilizing prominent experts and advanced equipment. The main goal of the research and development unit is to create innovative solutions to meet customer needs and enhance competitiveness in domestic and international markets. This approach has led to the production of high-performance products that comply with global standards.

Products quality

Commitment to quality at Farabin Farayand Sharif is an undeniable principle. We produce products at the highest possible level of manufacturing and quality by strictly adhering to the most rigorous quality standards and using high-quality raw materials. Quality control is carried out at all stages of production, from the selection of raw materials to the final product, to ensure that every product leaving the factory meets the highest quality standards and brings complete customer satisfaction.

Providing various raw materials for the polyurethane industry in the field of rigid, semi-rigid, and soft foams has led this company to focus on ensuring the quality of the raw materials and the final produced product. For this purpose, the chemical and mechanical properties of materials and products are examined at all stages. Properties such as viscosity, density, water percentage, and pressure and tensile tests are conducted in accordance with international standards in the quality control laboratory of Farabin Farayand Sharif.

It should be noted that in 2024, this company managed to receive the IMF ISO certifications, which include ISO 9001, ISO 14001, and ISO 45001.

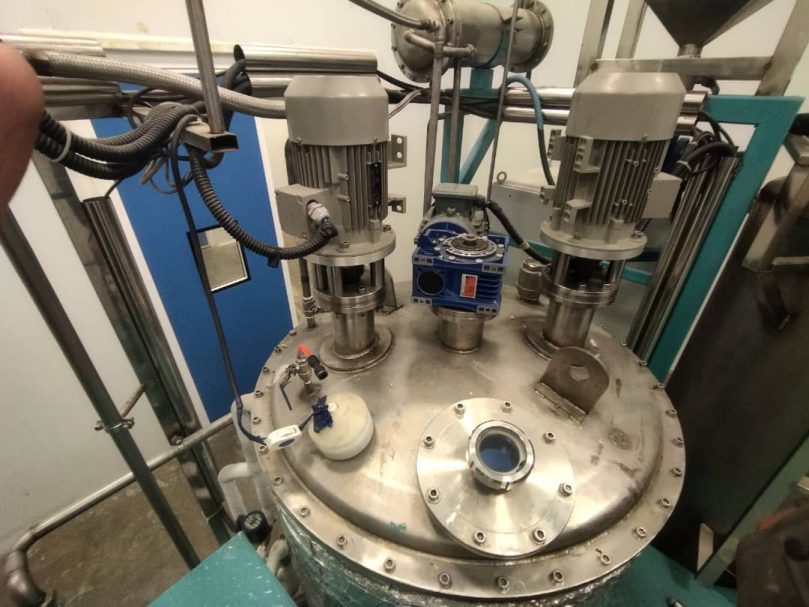

The production unit of Farabin Farayand Sharif, by leveraging advanced technologies and modern equipment, produces high-quality products with unique features. This unit constantly interacts with the research and development unit to bring the latest technologies and scientific findings into mass production. Furthermore, all production processes are carried out with precision and complete oversight to produce products with the highest quality and competitiveness in the global market.

Green production is one of the main pillars of Farabin Process Sharif’s strategy. We are committed to environmental preservation and reducing the environmental impact of our production processes. This commitment

Support unit

One of the most important concerns of polyurethane customers is ensuring production capability and appropriate quality properties, which often makes them hesitant to use materials different from those they’ve previously used. To address this, Farabin Process Sharif Company is committed to having its specialists present at the customer’s production line to perform any adjustments and setup, as well as providing 24/7 support via the mobile number listed in our contact section. Therefore, our commitment to supporting your purchase will remain steadfast around the clock.

Our Vision

The vision of Farabin Process Sharif Company is to become one of the leading suppliers of raw materials for polyurethane foams at both national and international levels. We aim to develop new products and expand our markets worldwide by focusing on innovation, quality, and sustainability. Through close collaboration with universities, enhancing our research and development capabilities, and maintaining high-quality standards, we intend to break new ground in this industry and become an influential and sustainable company in global markets.

Our Values and Ideals

- Honesty and Integrity

- Responsibility

- Commitment to Quality

- Customer Satisfaction Priority

- Up-to-date and Innovative Product Design

- Environmental Preservation

- Value and Dignity of Human Resources

- Teamwork

- Constructive Interaction with Colleagues

April 2024

Obtaining Manufacturing Supplier Grade from Saipa

February 2024

Visit by the Vice President for Science and Technology to Review Achievements

November 2023

Receiving Approval from Iran Khodro

November 2023

Visit by Iran Khodro Company to the Production Line

July 2023

Obtaining Operational License

July 2023

Obtaining Operational License

June 2023

Obtaining Approval from the Largest Private Sector Seat Manufacturer

June 2023

Visit by Saipa Company to the Production Line

June 2023

Environmental Approval

February 2023

Knowledge-Based Certification

December 2022

Nanotechnology

September 2022

Three-Party Agreement with SAPCO

June 2022

Production Line Launch

May 2022

First Approval from Saipa

June 2022

Visit by the Honorable Minister of Industry, Mine, and Trade to Review Achievements

January 2022

Establishment in Sharif Science and Technology Park

December 2021

Presidential visit of achievements

August 2021

Localization of Polyurethane Materials

August 2021

Acquisition of Indigenous Knowledge

2020

Company Establishment

CEO's Message

Mohammad Shivapour

CEO

In recent years, the increase in the level of sanctions has led to higher import costs, including the raw materials needed by key industries. Moreover, with the rising exchange rates, many manufacturers whose processes depend on imported raw materials or components have been doubly affected. Additionally, as the cost of final products increases, their market is harmed due to the economic difficulties faced by buyers. Unfortunately, many industries have encountered significant challenges in both sourcing and selling.

Therefore, utilizing domestic capacities and capabilities for localization and domestic production of the above-mentioned items can reduce the foreign exchange costs of products, decrease dependency on foreign sources, and help preserve economic enterprises and employment, ultimately reducing the production costs of domestic goods.

Farabin Farayand Sharif Company is striving to prioritize the development of technology in production and industry by relying on domestic capabilities, thereby making significant strides toward realizing a resilient economy.

In this regard, the localization of raw materials for producing various industrial foams, particularly polyurethane foam, has been identified as the most important product of this company.